In plumbing and gas systems, polytetrafluoroethylene (PTFE) tapes are used to seal the threads of pipework and fittings. Before tightening a fitting, the tape can be placed on the threads of piping installations. The tape acts as a stopgap and an efficient seal to prevent gas or water from exiting the system through a fitting’s threads. Read More…

Carolina Tape & Supply Co. is a distributor & custom tapes converter offering 100% satisfaction. As one of the leading tape suppliers in the nation, Carolina offers an array of quality products & services to your company.

CS Hyde is a leading distributor and converter that supplies a wide variety of high performance tapes with pressure sensitive adhesive. Our tape is available in materials such as Teflon™ Fluoroplastic, Kapton®, UHMW, Silicone, and many more. Since our fouding in 1996, our team at CS Hyde has continued to be committed to our customers and building long-term relationships by providing top...

CFS produces industrial masking products and flexible, converted materials such as gaskets, spacers, thermal pads, and EMI shielding for finishers, OEMs, and related suppliers. Please visit customfabricate.com to request information or to browse our selection of products online.

As a tape supplier our products serve many diverse industries such as aerospace, artistry, graphic arts, food and drink as well as many others! For over forty years we have been providing the highest quality tape products with the widest selection. Just a few examples of the products we offer are 3M masking, Teflon, gaffers tape as well as many others. To learn more about what we may be able to...

Budnick Converting is a family-owned custom converter and distributor of adhesive tapes, foams, and other flexible materials. We have over 70 years of experience in the tape and converting industry and offer adhesive tapes, foams, films, foils, and other specialty materials from every major manufacturer. Our primary converting services include slitting, die-cutting, printing, spooling,...

At Penmar Industries, we take pride in being trusted tape suppliers dedicated to providing adhesive solutions that meet the demands of modern industry. We supply an extensive range of pressure-sensitive tapes, including packaging, masking, double-coated, and specialty tapes, designed to deliver reliable performance in even the most challenging applications.

More PTFE Tape Manufacturers

The polytetrafluoroethylene tape line is offered in singles or multipacks and is also available in gas quality and drinkable water grade. Thread seal tape lubricates, enabling deeper thread seating, and also aids in preventing thread seizing during unscrewing. The tape aids in sealing the connection without stiffening or making it more challenging to tighten but rather makes it simpler to tighten. It also functions as a flexible filler and thread lubricant. Additionally, it shields the threading of both parts from physical damage and close touch and aids in sealing and preventing connection leaks.

Types of PTFE Thread Tapes

Other performance PTFE tape varieties are available in the packing, telecommunications, manufacturing, and aerospace sectors. Coated, Skived, calendared, extruded, skived, and laminated PTFE tapes are popular. The manufacturing methods used to create the multiple kinds of PTFE tapes distinguish them from one another. These procedures are responsible for the high density, elasticity, and tensile strength performance qualities that distinguish PTFE tape from other materials.

Skived PTFE Thread

Skived PTFE Tape is created by shaving or "skiving" PTFE blocks to the desired nominal film thickness. Consider an old-fashioned spindle potato peeler as an illustration. The potato is positioned on the spindle, which is turned by hand, and the outer layer of the potato is peeled off using a spinning knife. Similar steps are used in the production of skived PTFE. However, to produce the necessary film thickness, a high starting torque motorized shaft is rotated against a stationary blade across the length and breadth of the PTFE billet. Once skiving is completed, PTFE tape passes through a treatment procedure to permit an adhesive layer to be sprayed on the film, generating Skived PTFE tape.

Calendared PTFE Tape

This is a sheet or film made from melted PTFE polymers. This is accomplished via a device that uses rollers under high heat and pressure to compress and shape PTFE into the correct film thickness.

Advantages of Calendared PTFE

- Smooth surface

- Diminished skive lines

- Outstanding thickness accuracy

PTFE Coated Tape

These PTFE tapes are typically constructed from fiberglass fabric substrates with Teflon PTFE dispersion coated on them. These have a PTFE coating that offers a slippery, anti-friction-releasing surface, and they are comprised of finely bound fiberglass fibers that offer dimensional stability. PTFE-wrapped fiberglass tapes come in two primary grades: standard and ultra-premium. The woven fiberglass fibers' quality and the PTFE coating's thickness distinguish these varieties. These tapes use either silicone or acrylic adhesive for their two sticky backing systems. Silicone is widely employed in applications with high temperatures or simple removal and clean release. Acrylic applications require a greater initial tack adhesion or a stronger bonding adhesion. A PTFE-covered fiberglass specialized tape known as "Zone Tape" is used for purposes that only need adhesive on specific areas of the tape, leaving the middle part of the tape as the non-sticky part, "free zone."

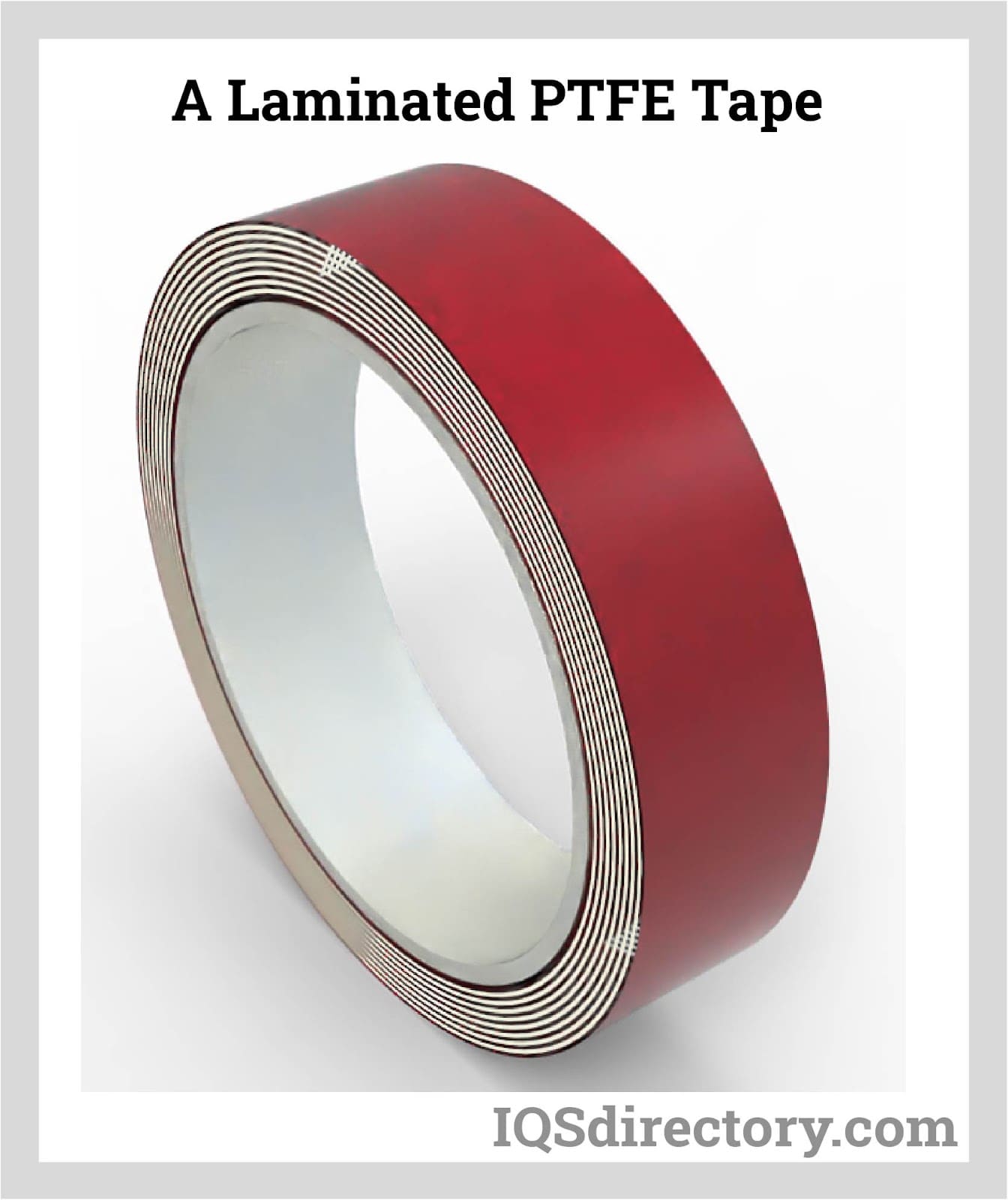

Laminated PTFE Tape

The same glass strands used to cover PTFE fiberglass are used in laminated PTFE tapes, but PTFE is laminated onto the fiberglass to produce a more resilient and long-lasting surface. Comparing laminated PTFE tapes to conventionally coated PTFE tapes, coated PTFE tapes are much more flexible and have a longer application life.

Applications of PTFE Tape

- Skived PTFE is advised for insulating applications due to its high insulating strength, releasing characteristics, and chemical and temperature tolerance. Standard skived tapes have a 300% elongation, making them extremely conformable and ideal for masking applications. Thick gauge "FAT" PTFE tape can make a dielectric insulator, a high thermal barrier, or a non-stick separator when gap bridging, separating, or insulating materials. Skived PTFE tape is the best insulator for electronic applications because of its high dielectric strength.

- PTFE laminate fabrics are suggested for applications where durability and non-stick qualities are necessary. Form-fill-seal machines are frequently used in the packaging industry to wrap heated wires. They are also utilized as release liners on conveyor systems to reduce friction in places with heavy traffic. Due to the strength properties of the fiberglass and the releasing qualities of PTFE, CS Hyde suggests using these PTFE polyester tapes as a diaphragm gasket material.

Choosing the Proper PTFE Tape Company

To make sure you have the most productive outcome when purchasing PTFE tape from a PTFE tape company, it is important to compare at least 4 to 5 companies using our PTFE tape directory. Each PTFE tape company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each PTFE tape company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple PTFE tape companies with the same message.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services