Masking tape is a type of adhesive tape that temporarily conceals surfaces where finishing work is not intended. Soldering, blasting, spraying, coating, plating, and polishing are temporarily protected by masking tapes while these processes are performed on surrounding surfaces. The tape contains a pressure-sensitive adhesive that can be easily torn and dispensed. The adhesive used in the making of a masking tape is the key element since it leaves no residue, which makes the tape extremely useful for carrying out many tasks. Read More…

Carolina Tape & Supply Co. is a distributor & custom tapes converter offering 100% satisfaction. As one of the leading tape suppliers in the nation, Carolina offers an array of quality products & services to your company.

CS Hyde is a leading distributor and converter that supplies a wide variety of high performance tapes with pressure sensitive adhesive. Our tape is available in materials such as Teflon™ Fluoroplastic, Kapton®, UHMW, Silicone, and many more. Since our fouding in 1996, our team at CS Hyde has continued to be committed to our customers and building long-term relationships by providing top...

CFS produces industrial masking products and flexible, converted materials such as gaskets, spacers, thermal pads, and EMI shielding for finishers, OEMs, and related suppliers. Please visit customfabricate.com to request information or to browse our selection of products online.

As a tape supplier our products serve many diverse industries such as aerospace, artistry, graphic arts, food and drink as well as many others! For over forty years we have been providing the highest quality tape products with the widest selection. Just a few examples of the products we offer are 3M masking, Teflon, gaffers tape as well as many others. To learn more about what we may be able to...

Budnick Converting is a family-owned custom converter and distributor of adhesive tapes, foams, and other flexible materials. We have over 70 years of experience in the tape and converting industry and offer adhesive tapes, foams, films, foils, and other specialty materials from every major manufacturer. Our primary converting services include slitting, die-cutting, printing, spooling,...

At Penmar Industries, we take pride in being trusted tape suppliers dedicated to providing adhesive solutions that meet the demands of modern industry. We supply an extensive range of pressure-sensitive tapes, including packaging, masking, double-coated, and specialty tapes, designed to deliver reliable performance in even the most challenging applications.

More Masking Tape Manufacturers

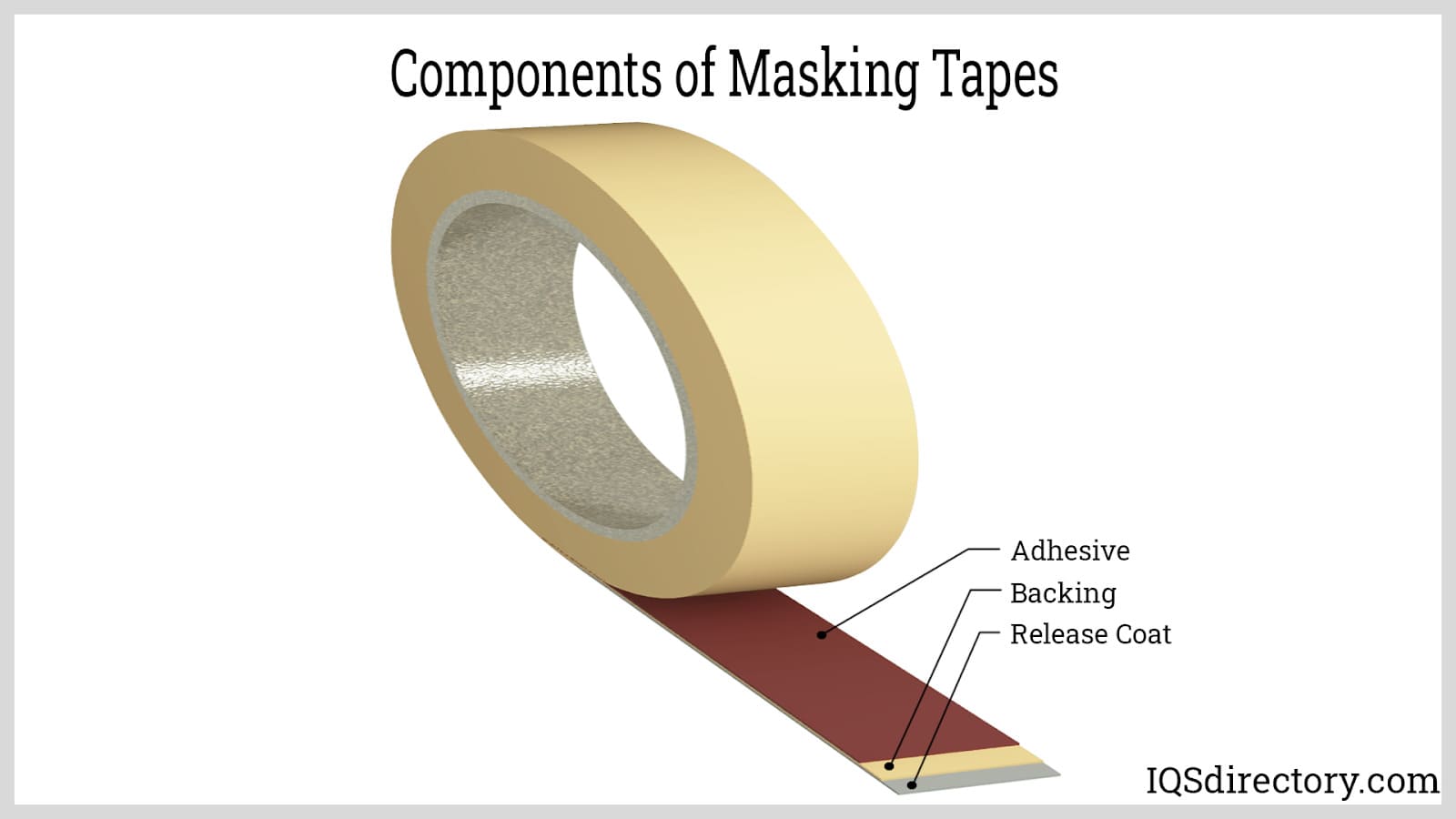

Components of Masking Tapes

Masking tape, a type of pressure-sensitive tape, is a versatile adhesive product used in a wide range of industries, from painting and automotive refinishing to electronics manufacturing and general industrial applications. Understanding the fundamental components of masking tapes is crucial for selecting the right tape for your specific needs and ensuring optimal performance.

A typical masking tape consists of two essential layers:

- Backing: The backing is often a thin, moist crepe paper that can be easily torn by hand, offering excellent conformability to irregular surfaces. In advanced applications, other materials like polyester, glass, or foil are also used as backing for enhanced durability and specialized performance.

- Adhesive Layer: The adhesive layer may be solvent-free, hot melt, or acrylic-based, selected based on the required level of adhesion and environmental resistance. The choice of adhesive directly influences the tape’s ability to stick securely during use and remove cleanly without residue.

When you’re searching for the best masking tape for your project, consider both the backing and adhesive types as critical selection criteria.

Materials Used for Masking Tapes

Masking tape manufacturers utilize a variety of materials to engineer tapes optimized for different environmental conditions, surface types, and industry-specific requirements. The choice of backing material greatly affects the tape's temperature resistance, flexibility, strength, and removability.

- Paper: Paper backings are the most common due to their cost-effectiveness and ease of use. Typically made from kraft or crepe paper, these tapes are ideal for general-purpose applications and provide good paint lines.

- Polyester: Polyester-backed masking tapes offer high resistance to solvents, excellent aging characteristics, and clarity. They are commonly used in powder coating, plating, and electronics manufacturing where dimensional stability and chemical resistance are required.

- Glass: Reinforced with glass or fiberglass fibers, these tapes possess superior heat resistance (up to 302°F/150°C) and tensile strength, making them suitable for high-temperature masking and insulation in industrial processes.

- Foil: Metal foil backings, such as aluminum or lead, provide excellent reflectivity, heat resistance, and electrical conductivity. These are often used for EMI/RFI shielding, HVAC applications, and masking in harsh thermal environments.

- Ceramic: Backings made from ceramic textiles or ABS fibers are engineered for extreme heat resistance, used in specialized high-temperature masking applications such as plasma spraying or furnace operations.

- Foam: Foam-backed masking tapes utilize polyolefin foams to provide cushioning, gap filling, and vibration damping. These are often used in automotive, electronic assembly, and gasketing applications.

Due to the temporary nature of masking tape, the adhesive must be carefully selected to prevent unwanted residue and ensure clean removal. This makes the adhesive formulation a key factor in end-user satisfaction and process efficiency.

There are four main adhesive bases for masking tapes:

- None: Some specialty masking tapes are non-adhesive and rely on friction or wrapping techniques for temporary holding. These are rarely used in traditional masking but may be found in niche industrial processes.

- Rubber: Rubber-based adhesives are known for their flexibility and strong initial tack. They are suitable for general-purpose masking and applications where quick stick and easy removal are required.

- Acrylic: Acrylic adhesives provide strong shear and peel strength, excellent weatherability, and resistance to UV radiation and aging. They are ideal for outdoor masking, automotive refinishing, and industrial painting where durability is a priority.

- Silicone: Silicone-based adhesives offer exceptional temperature resistance (up to 608°F/320°C) and clean removal from a wide range of surfaces. These tapes are commonly used in powder coating, PCB manufacturing, and other high-heat environments.

Are you unsure which masking tape material or adhesive is right for your next project? Contact a masking tape specialist to discuss your application requirements and receive expert recommendations.

Types of Masking Tape

Masking tapes are engineered for specific tasks and environments. Selecting the correct type of masking tape enhances performance, ensures clean results, and prevents costly rework. Below are some of the most common and specialized masking tapes available on the market:

Plating Tape

Red Plating tape features a durable polyester backing and a high-performance silicone adhesive. It is primarily used on circuit boards during tin/lead stripping and gold plating processes. This tape is formulated to resist acids, chemicals, and extreme processing temperatures, making it invaluable in electronics manufacturing and metal finishing. In addition, plating tapes can be used for masking during painting and varnishing on silicone paper films.

Painter’s Tape

Painter's tape is a specialized masking tape designed for painting projects—both professional and DIY. Used to protect surfaces that should not be painted, it ensures clean, sharp paint lines and prevents bleed-through. Automotive refinishing, home improvement, and decorative wall painting are common use cases. High-quality painter’s tapes are engineered for easy removal without damaging delicate surfaces or leaving adhesive residue. Looking for the best painter’s tape for crisp lines? Compare painter’s tape grades by surface type and paint compatibility before buying.

High-Temperature Resistance Tapes

High-temperature resistance tape is made with a polyester film and a specially formulated high-temperature adhesive. This type of tape is widely used in the electronics industry, powder coating, wave soldering, and other manufacturing processes that demand intense heat resistance and electrical insulation. These tapes are capable of withstanding prolonged exposure to high temperatures without degrading or leaving residue, making them essential in high-reliability environments. Wondering if high-temp tape is right for your process? Ask about the maximum operating temperature and adhesive compatibility for your substrates.

Vinyl Tape

Vinyl tape, also known as insulating tape, is a pressure-sensitive tape primarily used for electrical insulation. Its stretchable, water-resistant backing makes it ideal for wrapping wires, marking safety zones, color coding, and bundling cables. Vinyl masking tapes are valued for their conformability, abrasion resistance, and reliable adhesion to a variety of substrates. Are you selecting vinyl tape for electrical work? Compare dielectric strength and UL certification to ensure safety and code compliance.

Specialty Masking Tapes

In addition to the tapes above, specialty masking tapes are available for unique requirements such as:

- UV-resistant masking tapes for outdoor applications and protection from sunlight degradation.

- Double-sided masking tapes for temporary mounting and holding during assembly or construction.

- Automotive masking tapes specifically engineered for body shops and refinishing, offering superior conformability and clean removal from automotive paints and plastics.

- Fine line masking tapes for intricate designs, striping, and two-tone painting in automotive and aerospace industries.

Have a unique application? Request samples or technical data sheets from a masking tape supplier to evaluate specialty tapes for your use case.

Masking Tape Specifications

Understanding masking tape specifications is essential for choosing the ideal tape for your process. Key specifications include width, thickness, adhesion, tensile strength, elongation, and temperature resistance. Focusing on these parameters helps ensure reliable performance and project success.

Masking Tape Size (Width)

The width of masking tape is measured across its parallel edges and is available in various standard widths, typically ranging from 3mm (1/8 inch) to 72mm (3 inches) or more. Narrow-width tapes are perfect for precision work, such as masking tight corners, pinstriping, or detail painting, while wider tapes are chosen for masking off large surfaces or providing better coverage. Selecting the appropriate width reduces the risk of paint seepage and labor costs associated with taping multiple strips.

Masking Tape Thickness

Masking tape thickness is the distance between the carrier (backing) and adhesive, usually measured in mils (thousandths of an inch) or microns. Thicker tapes offer greater strength, durability, and resistance to tearing or puncturing, which is advantageous in abrasive processes like sandblasting or powder coating. However, very thick tapes may not conform as easily to curves or irregular surfaces. When evaluating thickness, consider the trade-off between robustness and flexibility based on your application.

Adhesion and Tack

The adhesive strength, measured as “tack,” determines how well the tape sticks to a surface. High-tack masking tapes are ideal for rough or textured surfaces, while low-tack tapes are better suited for delicate finishes or freshly painted walls. Manufacturers often publish peel adhesion values (in ounces/inch or N/cm) to help buyers compare options. Want to avoid surface damage? Ask your supplier for suggested adhesion levels for your substrate type.

Temperature Resistance and Durability

Temperature resistance is a critical factor, especially in industrial painting, powder coating, or electronics manufacturing. Ensure the masking tape’s maximum operating temperature exceeds your process requirements. Durability factors, such as UV resistance, moisture resistance, and chemical compatibility, should also be considered for applications in harsh or outdoor environments.

Masking Tape Applications

Masking tapes are indispensable across a range of industries due to their ease of use, clean removability, and adaptability to various processes. Common applications include industrial masking, painting, surface protection, and assembly operations. Below are some typical and advanced masking tape uses:

- Painting and Surface Protection: Widely used in automotive refinishing, home improvement, furniture manufacturing, and industrial painting to mask off areas for crisp paint lines and protect surfaces from overspray or damage.

- Electronics Manufacturing: Used for masking during wave soldering, conformal coating, and circuit board assembly to shield sensitive components and provide electrical insulation.

- Thermal Spraying and Powder Coating: High-temperature masking tapes protect surfaces during processes involving intense heat and abrasive particles.

- Shot Peening and Anodizing: Specialized tapes are used to mask off areas during chemical conversion processes, metal coating, or mechanical treatments.

- Sandblasting and Grit Blasting: Durable, thick masking tapes withstand abrasive forces and prevent unwanted material removal on protected surfaces.

- Bundling and Labeling: In packaging, logistics, and warehousing, masking tapes are used for temporary bundling, labeling, and color coding of products.

- General Repairs and Temporary Fixes: Masking tape’s easy tearability and repositionability make it a go-to solution for quick fixes on job sites or in households.

Not sure how to use masking tape for your application? Explore our masking tape application guides or consult our technical support team for advice tailored to your industry.

Benefits of Masking Tapes

Masking tapes deliver numerous advantages, making them a staple in professional and DIY toolkits. Key benefits include:

- Excellent Adhesion and Consistency: Reliable tack ensures secure masking and clean paint lines, even on challenging surfaces.

- Moisture and Environmental Barrier: Acts as a seal against moisture, dust, and environmental contaminants in industrial and construction settings.

- Structural Strength: In some cases, high-strength masking tapes can supplement or replace mechanical fasteners such as bolts, rivets, or welds, especially in lightweight assemblies.

- Versatility Across Temperatures: Available in formulations suitable for cold, ambient, or high-temperature processes, ensuring performance in diverse environments.

- Clean Removability: Designed to peel away without leaving sticky residue or damaging surfaces, reducing rework time and material costs.

- Conformability and Flexibility: Easily adapts to curves, corners, and irregular shapes for precise masking and protection.

- Ease of Application and Removal: Most masking tapes can be torn by hand and repositioned during application, saving time and effort.

- Cost-Effective Solution: Offers an affordable way to achieve professional results, minimize cleanup, and protect valuable surfaces during processing.

- Color Coding and Identification: Available in multiple colors for organizing, marking, and differentiating products or workflow stages.

Looking for masking tape with specific benefits? Filter masking tape products by adhesion, temperature rating, or surface compatibility to find the ideal solution for your project.

How to Choose the Right Masking Tape

Selecting the best masking tape for your needs involves evaluating project requirements, environmental factors, and surface characteristics. Here’s a step-by-step guide to making an informed purchase decision:

- Identify the application—painting, powder coating, electrical insulation, or general masking.

- Consider the substrate type and finish—choose low-tack for delicate surfaces, high-tack for rough surfaces.

- Assess the temperature exposure during application and removal.

- Determine required durability—UV resistance, water resistance, or chemical compatibility.

- Select the appropriate width and thickness for your coverage needs.

- Compare available products and request samples for testing if necessary.

- Review technical data sheets for specifications such as adhesion, tensile strength, and elongation.

Need help choosing? Contact our technical team or use our product comparison tool to evaluate masking tapes by specification, industry, or price.

Choosing the Right Masking Tape Supplier

Partnering with a reputable masking tape supplier ensures access to high-quality products, technical support, and tailored solutions for your business. To achieve the best results when purchasing masking tape, compare at least five companies using our list of verified masking tape suppliers. Each masking tape supplier profile highlights their experience, product range, quality certifications, and industry expertise.

Our intuitive supplier directory offers:

- Easy-to-navigate business profile pages detailing each masking tape manufacturer’s capabilities and specializations.

- A direct contact form for requesting information, samples, or quotes from suppliers.

- Convenient RFQ (Request For Quote) forms to contact multiple masking tape companies simultaneously.

- Patented website previewer to quickly review each supplier’s website and product offerings.

- Customer reviews and ratings to inform your purchasing decisions.

Ready to source masking tape for your next project? Use our supplier comparison tools, request samples, and download technical data sheets to make an informed buying decision.

Frequently Asked Questions About Masking Tape

- What is masking tape used for? Masking tape is used for masking surfaces during painting, protecting areas during surface treatments, bundling, color coding, and temporary holding in a variety of industries.

- Can masking tape be used on all surfaces? While masking tape adheres to many surfaces, choose the appropriate grade for delicate, rough, or specialty substrates to ensure clean removal and optimal adhesion.

- How do I remove masking tape without damaging paint? Remove masking tape slowly at a 45-degree angle, preferably when the paint is dry to the touch but not fully cured. For delicate surfaces, use low-tack or painter’s tape.

- What’s the difference between masking tape and painter’s tape? Painter’s tape is a type of masking tape formulated for clean paint lines and easy removal without residue, whereas general masking tape may have stronger adhesion and not be suitable for delicate finishes.

- How can I compare masking tape products? Review technical data sheets, compare adhesion and temperature resistance values, and request samples to evaluate performance in your specific application.

Still have questions? Explore our knowledge base or chat with a masking tape expert for real-time assistance.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services