Adhesive tape is a substance that has an adhesive film applied to attach or unite materials and protect surfaces. In addition, it has an adhesive-coated backing or carrier material, like paper, plastic film, fabric, foam, or foil, and, if appropriate, a release lining. For simplicity of use, coated backings are twisted into rolls and cut into narrow bands. To attach or unite materials and protect surfaces, adhesive tape is a substance that has an adhesive film applied. It has an adhesive-coated backing or carrier material, like paper, plastic film, fabric, foam, or foil, and, if appropriate, a release lining. For simplicity of use, coated backings are twisted into rolls and cut into narrow bands. Read More…

Carolina Tape & Supply Co. is a distributor & custom tapes converter offering 100% satisfaction. As one of the leading tape suppliers in the nation, Carolina offers an array of quality products & services to your company.

CS Hyde is a leading distributor and converter that supplies a wide variety of high performance tapes with pressure sensitive adhesive. Our tape is available in materials such as Teflon™ Fluoroplastic, Kapton®, UHMW, Silicone, and many more. Since our fouding in 1996, our team at CS Hyde has continued to be committed to our customers and building long-term relationships by providing top...

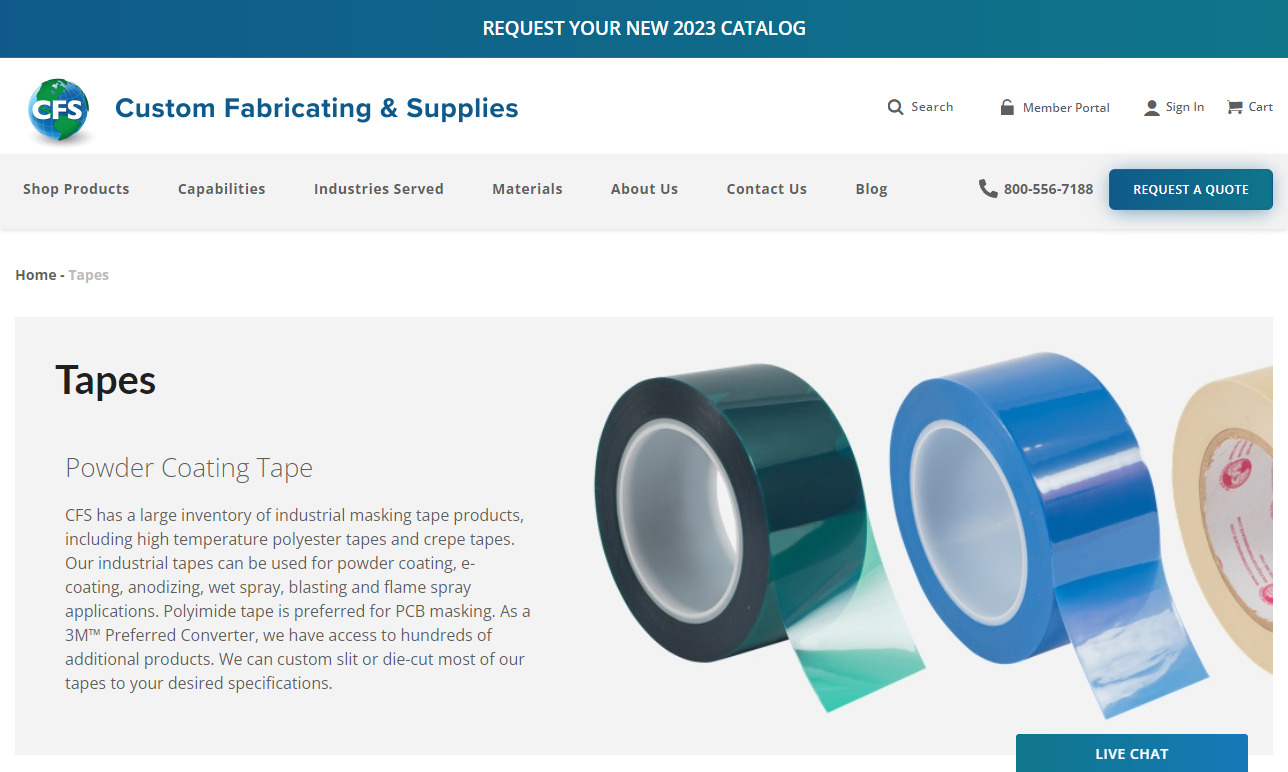

CFS produces industrial masking products and flexible, converted materials such as gaskets, spacers, thermal pads, and EMI shielding for finishers, OEMs, and related suppliers. Please visit customfabricate.com to request information or to browse our selection of products online.

As a tape supplier our products serve many diverse industries such as aerospace, artistry, graphic arts, food and drink as well as many others! For over forty years we have been providing the highest quality tape products with the widest selection. Just a few examples of the products we offer are 3M masking, Teflon, gaffers tape as well as many others. To learn more about what we may be able to...

Budnick Converting is a family-owned custom converter and distributor of adhesive tapes, foams, and other flexible materials. We have over 70 years of experience in the tape and converting industry and offer adhesive tapes, foams, films, foils, and other specialty materials from every major manufacturer. Our primary converting services include slitting, die-cutting, printing, spooling,...

At Penmar Industries, we take pride in being trusted tape suppliers dedicated to providing adhesive solutions that meet the demands of modern industry. We supply an extensive range of pressure-sensitive tapes, including packaging, masking, double-coated, and specialty tapes, designed to deliver reliable performance in even the most challenging applications.

More Adhesive Tape Manufacturers

Today's adhesive tapes, such as electrical, packaging, and painter's tape, are all created to fulfill the demands of a particular application. One of the most practical tools ever created, adhesive tapes come in various forms and are used in workplaces, homes, businesses, and other settings.

Steps in Manufacturing Adhesive Tapes

Step 1

Adhesive: First, after the adhesive is created, the material is prepared for coating by binding the adhesive to a solvent that facilitates its distribution onto the backing. Certain adhesives and solvents are utilized depending on the type of tape produced. Typically, hot melt or acrylic adhesives with acrylic and water-based solvents are employed.

Step 2

Coating: Next, to get the backing roll ready for coating, it is unwound. The type of tape created also determines the backing material. At this point, a thin, even layer of adhesive is applied to the backing, and as the solvent evaporates, the layer solidifies.

Step 3

Cutting: After the adhesive has dried, the backing is wound to form the roll. The cutting of the cylinders and packaging of the individual tape coils, ready for shipping, represent the final steps because the roll is still a sizable, wide band that combines multiple final products.

Types of Adhesive Tape

Foam Double-Coated Tapes

Open cell, low-density, double-sided polyester, and polyether foam tapes are the most common types of double-sided urethane foam tapes. They are reasonably priced and effectively insulate against noise, light, and dust. Usually, one side of these foams has a supporting adhesive.

This adhesive tape can be used to confirm and adhere the product to erratic surfaces. It may be shielded by a release liner, which is taken off and thrown away during installation.

Single-Coated Adhesive Tapes

Single-coated tapes typically have 1-10 mils thick supports and 2-5 mils adhesive. Acrylic, rubber, and silicone are the three types of single-coated adhesive tape. The most common types of backings are papers, polymer films, foils, nonwoven materials, and woven substrates.

With single-sided adhesive tape, a pressure-sensitive adhesive is applied on one side of a stretchy carrier adhesive tape material. This tape is used to attach other components together and adhere the product to the substrate. It may also have a removable release liner.

Double-Coated Adhesive Tapes

Double-sided (also known as double-coated) adhesive tape is made of a fabric or non-woven tissue carrier with a pressure-sensitive adhesive applied to both sides. A wide web laminator or a person can apply these adhesive tapes.

double coated tape

This thin, elastic carrier adhesive fabric is pressure-sensitive and adhesive-coated on both sides; typically, one side is covered by a separation liner and the other side is uncovered. Double-coated tape is used to join two substrates, even with varying textures. It’s also highly configurable, with the option of employing the same or different adhesives for the two adhesive layers. Double sided tape is ideal for bonding gaskets, insulating materials, attaching molding, securing electronic components, and more.

Adhesive Transfer Tapes

Adhesive transfer tape, also known as ATT, transfer tape, or unsupported tape, is made of a thin layer of adhesive covered in a handle-friendly liner. An adhesive transferring tape is used similarly to other double-sided tapes, where the lining is peeled off to attach the second substrate.

This product, also known as free film, is made out of a layer of pressure-sensitive adhesive without a carrier. One side is covered by a separation liner, and the other side is uncovered. In addition, due to the absence of a carrier, it is more expandable and conformable. ATT is perfect for attaching nameplates, second-surface printing signage or labels, and other ornamental substrates.

Uses of Adhesive Tapes

- Joining

- Masking

- Sealing

- Splicing

- Bundling

- Surface protection

Since they can be applied without machinery or specialized tools, adhesive tapes have become increasingly common. They come in sheets that can be unwrapped when required, are lightweight, and are simple to store. In contrast to conventional mechanical fasteners like nuts and bolts, adhesive tape doesn't require piercing or punching the substrate, which puts stress on the surface.

Choosing the Proper Adhesive Tape Supplier

To make sure you have the most beneficial outcome when purchasing adhesive tape from an adhesive tape supplier, it is important to compare at least 4 companies using our adhesive tape directory. Each adhesive tape supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each adhesive tape business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple adhesive tape companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

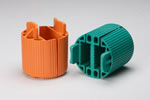

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services