An adhesive made specifically for use with electrical conduits is called electrical tape. It is specifically created with a non-conducting electrical substance. It is designed to insulate electrical wire and other items that conduct electricity from one another and protect people from shock. Read More…

Carolina Tape & Supply Co. is a distributor & custom tapes converter offering 100% satisfaction. As one of the leading tape suppliers in the nation, Carolina offers an array of quality products & services to your company.

CS Hyde is a leading distributor and converter that supplies a wide variety of high performance tapes with pressure sensitive adhesive. Our tape is available in materials such as Teflon™ Fluoroplastic, Kapton®, UHMW, Silicone, and many more. Since our fouding in 1996, our team at CS Hyde has continued to be committed to our customers and building long-term relationships by providing top...

CFS produces industrial masking products and flexible, converted materials such as gaskets, spacers, thermal pads, and EMI shielding for finishers, OEMs, and related suppliers. Please visit customfabricate.com to request information or to browse our selection of products online.

As a tape supplier our products serve many diverse industries such as aerospace, artistry, graphic arts, food and drink as well as many others! For over forty years we have been providing the highest quality tape products with the widest selection. Just a few examples of the products we offer are 3M masking, Teflon, gaffers tape as well as many others. To learn more about what we may be able to...

Budnick Converting is a family-owned custom converter and distributor of adhesive tapes, foams, and other flexible materials. We have over 70 years of experience in the tape and converting industry and offer adhesive tapes, foams, films, foils, and other specialty materials from every major manufacturer. Our primary converting services include slitting, die-cutting, printing, spooling,...

At Penmar Industries, we take pride in being trusted tape suppliers dedicated to providing adhesive solutions that meet the demands of modern industry. We supply an extensive range of pressure-sensitive tapes, including packaging, masking, double-coated, and specialty tapes, designed to deliver reliable performance in even the most challenging applications.

More Electrical Tape Manufacturers

Customization and Design of Electrical Tape

Electrical tape is a vital component in electrical insulation and wire management, available in a diverse range of specifications to meet the requirements of professional electricians, contractors, and DIY enthusiasts alike. Variations include color, backing thickness, total thickness, dielectric strength, tensile strength, width, backing material, adhesive type, length, storage stability, and even flame-retardant certifications. These characteristics are crucial factors for buyers seeking optimal performance and safety in electrical tape applications.

Black electrical tape is the most common due to its high resistance to UV radiation and durability in both indoor and outdoor environments. However, electrical tape comes in a spectrum of colors—each serving a specific purpose in electrical wiring identification. For instance, colored electrical tape is used to visually distinguish between different phases of cables, voltage levels, or ground wires. This adherence to color coding standards helps ensure safety, organization, and compliance with industry regulations.

Common color codes include:

- Brown tape: Denotes high voltage, phase A cables.

- Green tape: Used for earth-ground or ground wires, enhancing safety by clearly identifying grounding conductors.

- Blue tape: Indicates phase C cables or low voltage lines, often used in commercial and residential wiring systems.

- Red, Yellow, and White tapes: Each offers further distinction, supporting multi-phase systems or specific voltage ratings.

For additional safety, particularly in environments with exposure to moisture, heat, or chemicals, users may choose to wrap exposed wires with specialized foil tape or layered electrical tape for enhanced protection. Most electrical tapes are UL-certified (Underwriters Laboratories), meaning they meet stringent standards for fire resistance and flame retardancy, regardless of material composition, color, thickness, or width. This certification provides peace of mind that the tape is safe to use for electrical insulation and wire splicing, reducing fire hazards even in the event of overheating or short circuits.

How to Use Electrical Tape Safely and Effectively

Proper application of electrical tape is critical to ensuring long-lasting insulation, safe repairs, and effective cable management. To use electrical tape effectively:

- Preparation: Begin by ensuring the wires or connections are dry, clean, and free from debris. Contaminants can compromise adhesive performance and electrical insulation.

- Wrapping technique: Gently wrap the tape around the exposed wires, making sure that the tape unrolls smoothly and adheres well to the surface of the wire. Keep moderate tension as you wrap—tight enough to hold but not so tight as to overstretch the tape, which could reduce its insulating properties or cause it to lose shape over time.

- Seal gaps: Overlap each layer by half the tape’s width to ensure complete coverage, preventing water ingress and accidental contact with bare wires.

- Finishing: Firmly press down the end of the tape to secure it in place. Quality electrical tapes are designed to stay put for years, yet can be removed easily without leaving significant sticky residue.

Looking for step-by-step guides or video tutorials on electrical tape application? Explore our FAQ section for practical usage tips and troubleshooting common issues.

Considerations for Buying Electrical Tape

When evaluating electrical tape for purchase, it’s important to recognize product terminology and the specific use case. Electrical tape is also known as insulating tape or friction tape in some industries. If the tape is composed of plastic, particularly polyvinyl chloride (PVC), it may be labeled as PVC electrical insulation tape. Buyers should be careful not to confuse this with PTFE tape (polytetrafluoroethylene), which is primarily used for plumbing and pipe sealing applications.

PTFE tapes are renowned for their abrasion resistance and are frequently utilized to mark hazardous zones or highlight areas on the floor. However, they may leave adhesive residue when removed, potentially causing electrical problems if misapplied to wires. Mixing PVC and PTFE tapes can lead to complications such as adhesive build-up, reduced electrical insulation, or even code violations. If you’re unsure which tape is right for your project, review our in-depth comparison guide for side-by-side product analysis and recommendations.

Material selection is another critical factor in choosing the right electrical tape. Modern electrical tapes are manufactured from various plastics because of their excellent electrical insulation properties and flexibility. PVC tape remains the industry standard due to its flexibility, ease of tearing, and long-lasting performance. Polyvinyl chloride (PVC) electrical tape is often used in place of standard vinyl tape, offering superior water resistance, abrasion resistance, and corrosion resistance. While not entirely waterproof, PVC tape provides the moisture and chemical resistance required for most general-purpose electrical tape applications, making it suitable for indoor, outdoor, and industrial environments.

When shopping for electrical tape, consider these key decision factors:

- Adhesive type and strength: Ensure the tape adheres well to a range of surfaces, including cables, connectors, and terminals.

- Temperature rating: Choose a tape that maintains its properties under both high and low temperature extremes, especially for automotive, HVAC, or outdoor use.

- Dielectric strength: Look for high voltage resistance to prevent electrical arcing or insulation breakdown.

- Flame retardancy and safety certifications: UL listing or equivalent certifications guarantee compliance with industry safety standards.

- Physical durability: Resistance to abrasion, weather, UV exposure, and chemical contact will extend tape life and performance.

- Color coding options: Select tapes that support your wire identification or compliance requirements.

- Length and width: Choose rolls that match your project size and application needs.

Ready to compare brands and suppliers? Browse our top-rated electrical tape manufacturers and request product samples tailored to your application.

Waterproof Levels of Different Electrical Tapes

Waterproofing is an essential consideration for electrical tape selection, especially in outdoor, automotive, marine, and industrial environments where moisture exposure is likely. Below, we explore different types of electrical tapes and their waterproof properties:

Polytetrafluoroethylene (PTFE) Tape

PTFE tape, often called thread seal tape or plumber’s tape, is highly valued for its chemical resistance and ability to withstand prolonged moisture exposure. It is widely used for sealing pipe threads, preventing leaks in plumbing systems, and providing a barrier against corrosion. However, PTFE tape is not intended for electrical insulation—using it on wires can result in reduced safety, as it lacks the dielectric and flame-retardant properties of electrical tape. While PTFE adds some moisture resistance when layered under electrical tape, it is not a substitute for UL-listed electrical insulation tape in high-voltage or wet environments.

Rubber Electrical Tape

Rubber electrical tape is designed for demanding low-voltage and medium-voltage applications, offering superior stretch and conformability to irregular surfaces. It excels in environments where added moisture resistance is required, such as outdoor splices, automotive repairs, and temporary underwater connections. The self-fusing nature of rubber tape creates a watertight seal, making it more moisture-resistant than standard vinyl or PVC tapes. However, while rubber tape increases protection, it is not fully waterproof and may degrade with extended water exposure.

Mastic Tape

Mastic tape features a fully rubberized backing and a highly flexible adhesive, providing the highest level of moisture resistance among common electrical tapes. It is frequently used for sealing cable splices, underground connections, and outdoor installations. Mastic tape’s ability to conform, seal, and protect makes it an excellent choice for applications exposed to water, humidity, or harsh environmental conditions. If you’re searching for a waterproof sealing solution for electrical connections, mastic tape is often recommended by industry professionals.

Vinyl and PVC Electrical Tape

Vinyl and PVC electrical tapes are the most popular for general-purpose electrical insulation, offering a balance of flexibility, dielectric strength, and moderate moisture resistance. While these tapes resist splashes, humidity, and general weathering, they are not rated as waterproof for continuous submersion or high-pressure environments. For added waterproofing, they can be layered or combined with mastic or rubber tape.

Looking for Waterproof Electrical Tape?

Need help selecting the best waterproof tape for your project? Contact our experts or use our interactive tape selector tool for tailored recommendations based on your environment and performance requirements.

Electrical Tape Applications

Electrical tape’s versatility makes it indispensable in a wide range of industries and everyday scenarios. Below are some of the most common and innovative applications for electrical tape:

- Wire Insulation: Provides electrical insulation for exposed wires, cable splices, and terminations, preventing short circuits and accidental contact.

- Wire Bundling and Management: Organizes and secures groups of wires or cables, reducing clutter and improving safety in electrical panels, junction boxes, and home entertainment systems.

- Color Coding and Phase Identification: Assists electricians in quickly identifying circuit phases, voltage ratings, or ground wires through standardized color coding, supporting compliance with electrical codes.

- Temporary Repairs: Offers a fast, effective solution for patching minor wire or insulation damage until a permanent fix can be made.

- Labeling and Marking: Used to mark hazardous areas, label tools, or designate specific wiring functions.

- Sports and Recreation: Athletes use electrical tape to secure protective gear, mark boundaries, or provide extra grip on equipment such as hockey sticks or racquets.

- Musical and Stage Equipment: Musicians and stage crews rely on electrical tape to secure cables, reduce tripping hazards, and minimize noise interference from loose wires.

- Home Improvement and DIY: Homeowners use electrical tape for patching, bundling, arts and crafts, or even minor plumbing fixes.

- Automotive and Marine: Essential for insulating, bundling, or temporarily repairing wiring in vehicles, boats, and RVs exposed to vibration, heat, or moisture.

Curious about unique or advanced uses for electrical tape? Read our case studies for real-world examples and creative solutions from professionals across industries.

Choosing the Proper Electrical Tape Manufacturer

With countless brands and suppliers in the market, selecting the right electrical tape manufacturer can significantly impact project outcomes, safety, and long-term performance. Here’s how to make an informed decision:

- Compare multiple manufacturers: Don’t settle for the first option. Use our electrical tape directory to evaluate at least 4 to 5 manufacturers based on product range, certifications, and customer reviews.

- Review business profiles: Each manufacturer’s profile page highlights their core capabilities, production expertise, and areas of specialization—vital for sourcing custom or large-quantity orders.

- Direct communication: Use built-in contact forms to request more information, ask technical questions, or obtain detailed quotes tailored to your project needs.

- Website previewer: Take advantage of our patented website previewer to explore company websites and get a feel for their product lines, manufacturing standards, and client support.

- Streamlined RFQ process: Use our simple Request for Quote (RFQ) form to contact multiple manufacturers simultaneously, ensuring you get competitive pricing and comprehensive answers to your requirements.

Want to know what sets the best electrical tape manufacturers apart? Check out our manufacturer comparison guide and discover the key criteria for evaluating product quality, reliability, and after-sales support.

Frequently Asked Questions About Electrical Tape

What is the difference between PVC, vinyl, and rubber electrical tapes?

PVC and vinyl electrical tapes are often used interchangeably, both offering flexibility, moisture resistance, and moderate weather protection. Rubber electrical tape, on the other hand, is designed for higher moisture resistance, self-fusing properties, and superior conformability, making it ideal for outdoor or high-stress environments.

Can electrical tape be used outdoors or in wet conditions?

While high-quality PVC and vinyl tapes offer some moisture resistance, they are not fully waterproof. For outdoor, marine, or buried applications, consider using rubber or mastic tapes, which provide better sealing against water ingress. For continuous submersion, consult a specialist for tape rated for your environment.

Is electrical tape safe for high-voltage applications?

Always check the tape’s dielectric strength rating and verify UL or equivalent certifications. For high-voltage splicing or insulation, use tapes specifically designed for these conditions and follow local electrical codes and safety standards.

How long does electrical tape last?

When applied correctly and used within its rated environment, electrical tape can last for several years without significant deterioration. Factors such as temperature extremes, exposure to chemicals, UV radiation, or mechanical stress can affect its lifespan.

How do I remove electrical tape residue?

Gently peel the tape and use a residue remover or rubbing alcohol to clean remaining adhesive. Avoid using sharp tools that may damage wires or insulation.

Resources and Next Steps

- Search and compare electrical tape manufacturers

- Find the best electrical tape for your application

- Explore industry case studies and real-world applications

- Contact our experts for personalized recommendations

Whether you’re an electrician, contractor, maintenance professional, or homeowner, choosing the right electrical tape is essential for safety, reliability, and compliance. Use our resources above to make informed decisions and ensure your next electrical project is a success.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

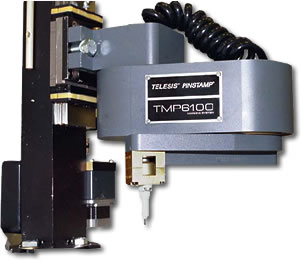

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

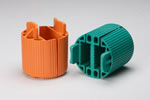

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services